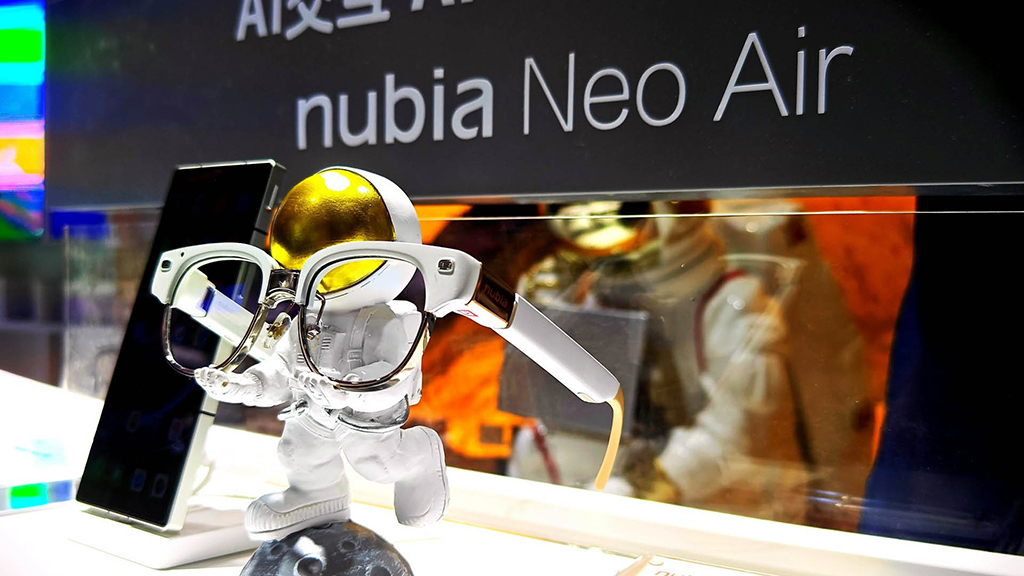

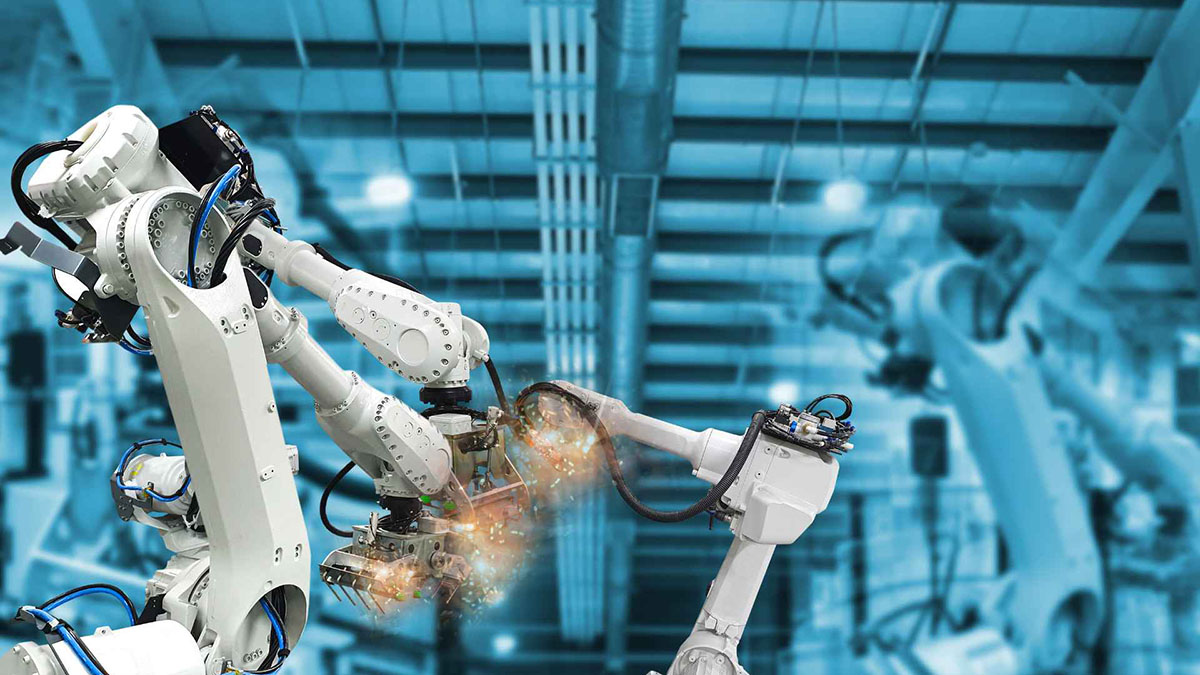

Addverb, a globally renowned leader in robotics and warehouse automation, proudly announces its partnership with PekaKroef in Odiliapeel in the Netherlands. This partnership represents a major step in automating PekaKroef’s logistics operations by introducing a fully automated pallet warehouse for storage and Goods-to-Person order picking.

Peka Kroef is a family business that specialises in fresh chilled potato products. Since 1970 they have been constantly pushing the boundaries of their products and production methods to provide their customers with even better service, which means even fresher, even easier and even tastier products.

Addverb’s cutting-edge automation technology is set to transform the logistics operations of PekaKroef. Boasting a storage density of 3.1 pallets/sqm, this innovation aims to quadruple picking efficiency. This will significantly streamline pallet-order fulfilment processes and boost overall productivity, empowering PekaKroef to meet its delivery commitments for its B2B customers.

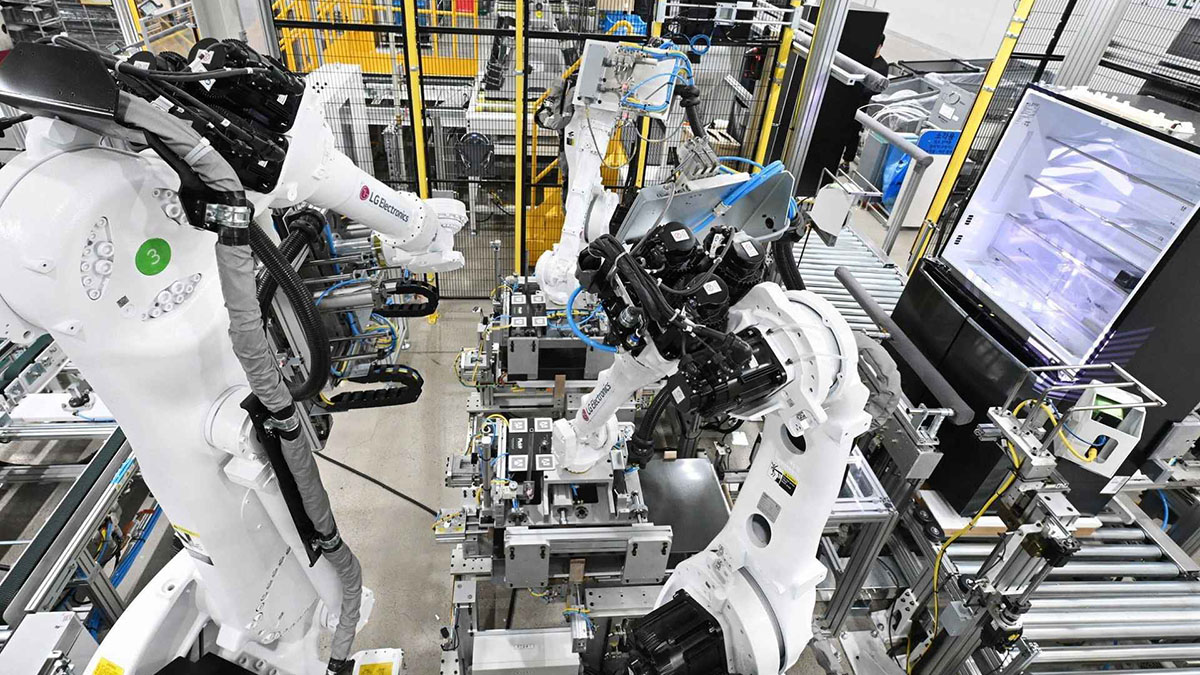

The solution incorporates flexible solutions such as 4-way pallet shuttles for pallet movement, rail-guided vehicles (RGVs) for efficient, high-speed pallet transport; and goods-to-person workstations to optimize the picking process, enhancing accuracy and speed. A seamless connection between the production factory and the automated storage and retrieval system will ensure smooth and efficient operations.

PekaKroef’s CEO, Edwin Holleman highlighted the partnership, stating, “This solution will revolutionize our storage capacity by maximizing space efficiency, enabling us to broaden our product range and seamlessly incorporate new business segments. Beyond just space, the system will be energy efficient, embodying our commitment to sustainability. These innovations are set to transform our logistics flow, and will elevate the performance of our entire operation.“

Pieter Feenstra, EMEA CEO of Addverb, said, “We are thrilled to collaborate with PekaKroef in this transformative project. Our advanced automation technologies will provide them with the tools they need to continue their legacy of quality and reliability while embracing the future of logistics.”