On March 14, Chamlion, a digital dental expert, will appear at the IDS in Germany, exhibiting the world’s first dental 3D printing service cloud platform at booth K091 in Hall 11.3, providing one-stop solutions for global dental processing customers.

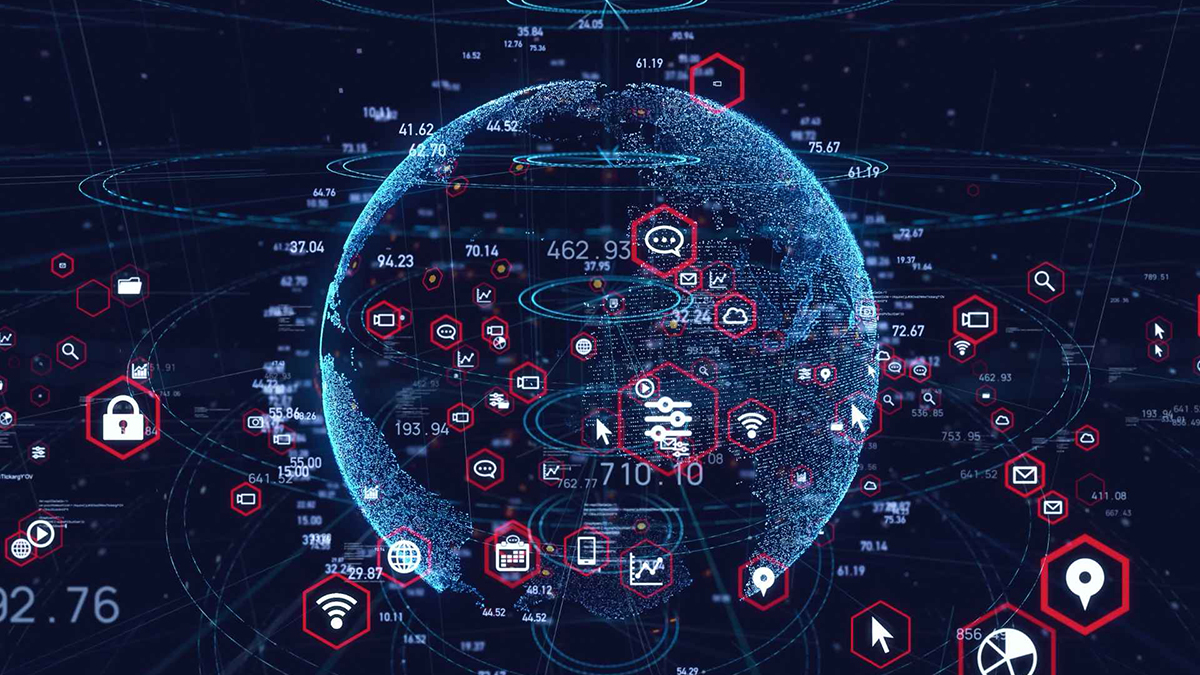

Visiting Chamlion’s booth will help people have a comprehensive understanding of our cloud platform, which for the first time applies the HAAS model (HAAS, Hardware as A Service) in the field of dental 3D printing, and connects all 3D printers online to build distributed cloud factories with the ability of intelligent manufacturing, greatly reducing the cost to end users. Dental labs can enjoy advanced and efficient 3D printing service without purchasing expensive equipment.

n important platform for Chamlion to communicate face-to-face with customers. People can experience the service of Chamlion cloud platform at the Chamlion booth. Customers only need to place an order online, and the cloud factories distributed around the world can receive processing tasks in no time. Through intelligent 3D design, data processing, and 3D printing manufacturing, the order can be completed with high efficiency, high quality, and low cost. The delivery of semi-finished dental products only takes 24 hours. The current Chamlion cloud factory can process the data of more than 80,000 dental crowns and 8,000 partial frameworks per day.

Chamlion is an innovator in the digital workflow of dental processing, and the cloud factory brings new business options, giving dental labs more choices and convenience. In addition to 3D printing services, dental labs can also choose one stop design, data processing, post processing therefore benefitting from the digital revolution with low costs. At present, Chamlion operates in 27 countries including the United States, Canada, Italy, Turkey, Vietnam and Dubai, and is establishing more than 260 cloud factories to provide one stop service for thousands of dental labs.