Smart manufacturing & stringent process control enhance TPU quality. ICP DAS – BMP (Biomedical Polymers), a Taiwan-based supplier of medical-grade TPU (thermoplastic polyurethane), acts as a front-runner who deploys IIoT systems in a smart factory to maintain lot-to-lot consistency in TPU production. The company will showcase its prime quality TPUs to worldwide visitors at Medtec China 2023, June 1-3, Suzhou.

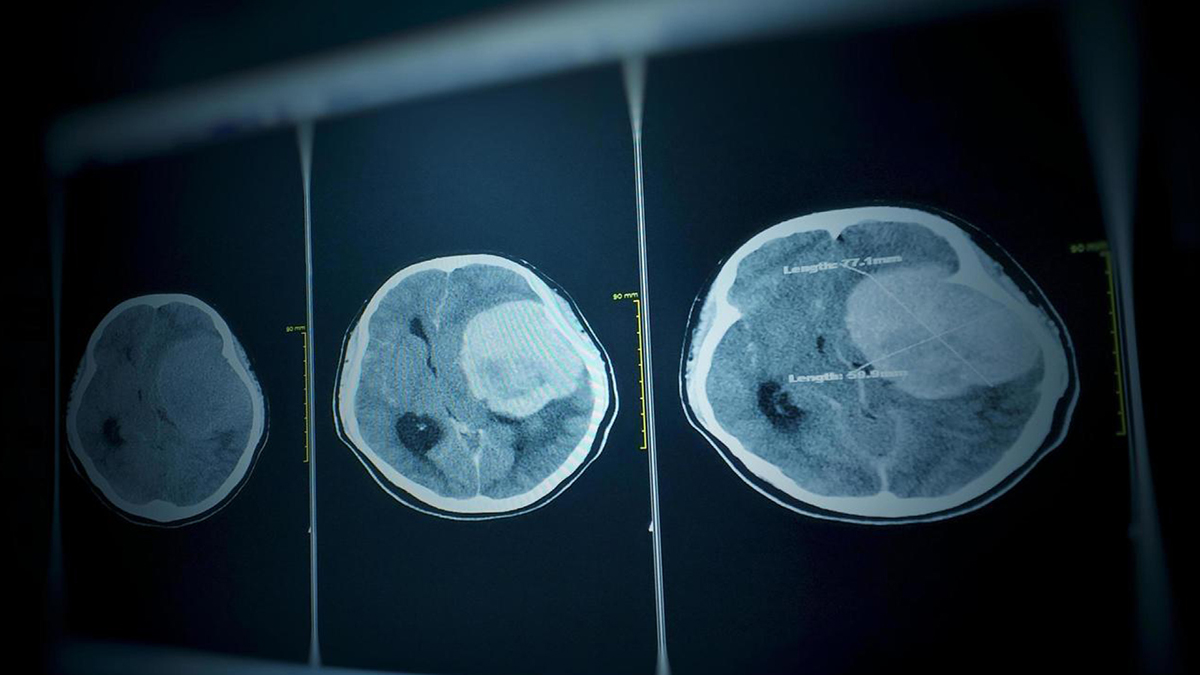

ICP DAS – BMP manufactures and offers three product series, including Alithane™ (ALP series), Durathane™ (ALC series), and Arothane™ (ARP series) with varying percentages of radiopaque fillers to suit customer-specific needs. This year, ICP DAS – BMP has introduced two new products, the ARP-B40 and ALC-B40, which provide 40% loading of barium sulfate. Additionally, samples of tubing containing 40%, 60%, 70%, and 80% tungsten will be showcased at our exhibition booth.

Materials with high consistency are essential for medical device manufacturing. Therefore, ICP DAS – BMP places great importance on quality assurance and performs rigorous testing and thorough quality inspections for each batch of TPU produced. Besides, we constantly upgrade production lines through IIoT solutions to optimize manufacturing processes and increase productivity. The resultant shorter lead times further boost ICP DAS – BMP competitive edge.

ICP DAS — an industrial automation technology company with 30-year domain knowledge in automation, IIoT, and energy management — established ICP DAS – BMP. By leveraging the expertise and resources of ICP DAS, the BMP business unit is empowered to monitor machine status and environmental factors to optimize production efficiency and ensure consistent high-quality product.

Visitors are invited to stop by and experience our quality TPUs at booth C1-V412 from June 1-3 @ Suzhou International Expo Centre.