In the volatile world of global business, building a resilient B2B supply chain is no longer a “nice-to-have” — it’s critical for survival and long-term success. Whether the disruption comes from geopolitical crises, natural disasters, or rapid demand fluctuations, companies with resilient supply chains can adapt, recover, and even thrive. Here’s a comprehensive guide on how to build one.

- Understand & Map Your Supply Chain

- Visibility is foundational: Map not just your direct (tier-1) suppliers, but also second- and third-tier suppliers. According to supply chain resilience experts, deeper-tier mapping helps identify hidden risks.

- Identify critical nodes: Analyze which parts of the network are choke points — single-source suppliers, fragile logistics routes, or geographic risk zones.

- Use data: Leverage trade data, supply chain platforms, or ERP systems to build a real-time picture of supplier performance, lead times, and capacity.

- Diversify Strategically

- Multi-sourcing: Don’t rely on a single supplier for critical components. Use multiple suppliers across geographies to spread risk.

- Alternative routes: Build contingency logistics partners and routes. For example, have backup carriers and emergency shipping lanes.

- Modular design: Use standardized or modular parts that can be sourced from multiple suppliers to switch easily in case of disruption.

- Build Buffers & Redundancies

- Safety stock: Maintain buffer inventory at key nodes to absorb supply shocks.

- Redundant capacity: Plan for alternate manufacturing or warehousing capacity so you can reroute production if one site is compromised.

- What-if planning: Create scenario plans covering worst-case events (natural disaster, supplier failure, geopolitical risk) and define clear playbooks.

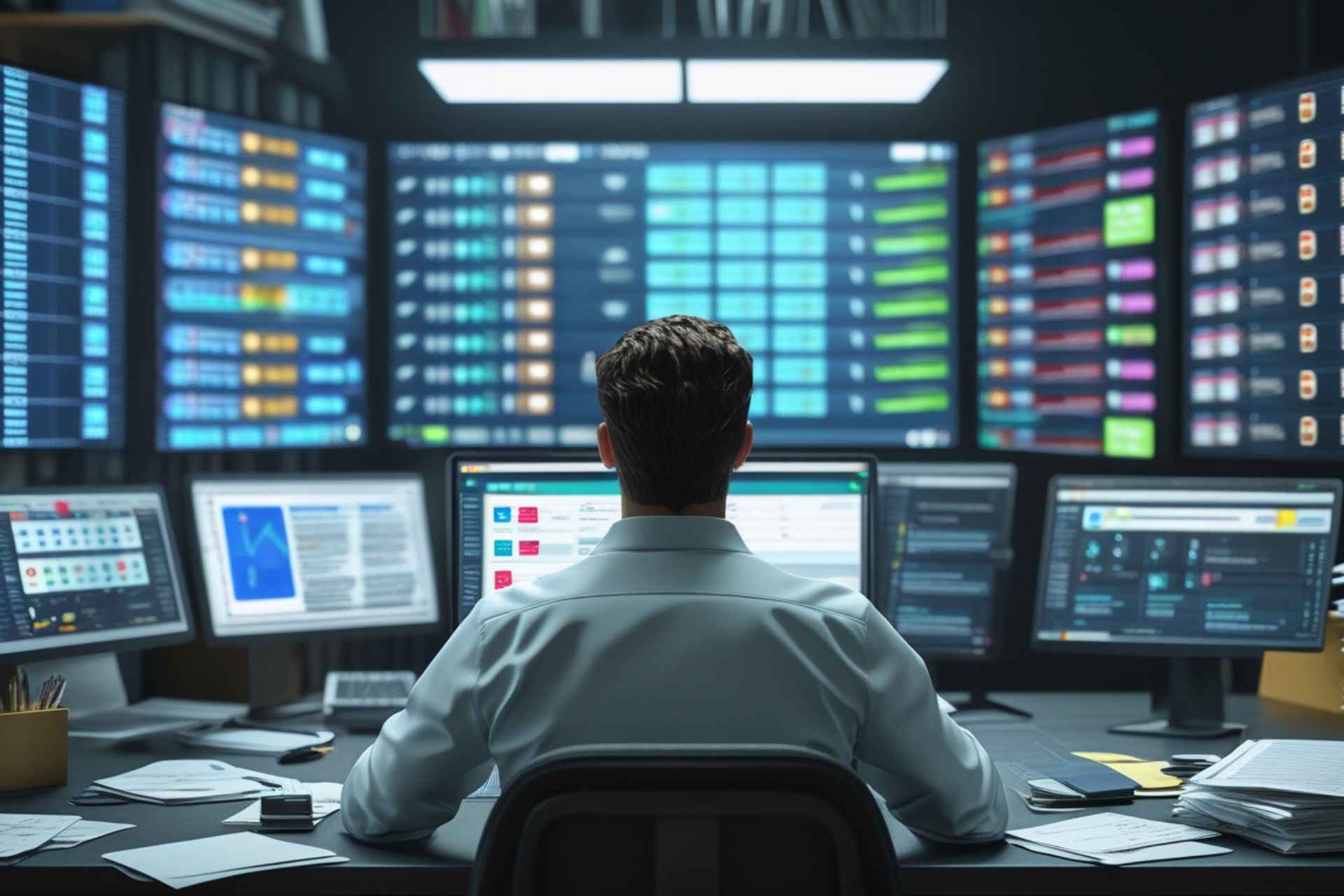

- Invest in Technology & Digital Tools

- Real-time tracking: Use IoT sensors, GPS, and real-time monitoring to track shipments and detect delays early.

- Centralized data platform: Implement an ERP, control tower, or SCM platform so all partners share a common source of truth.

- Advanced analytics: Use predictive forecasting, simulation, and modeling to anticipate demand shifts or disruption impacts.

- Emerging tech: Leverage AI, IoT, cloud computing, or even blockchain to improve transparency, trust, and agility.

- Strengthen Supplier Relationships

- Collaborative planning: Use joint planning, forecasting, and replenishment (CPFR) with key suppliers to align on demand and reduce surprises.

- Goodwill & trust: Build strong, long-term relationships so suppliers prioritize you during tight supply conditions.

- Compliance & enablement: Ensure your suppliers are digitally enabled (e.g., EDI integration) and compliant with your quality, ESG, or risk standards.

- Risk Management & Contingency Planning

- Risk assessment: Regularly assess risks (geopolitical, supplier financial health, operational) and prioritize them.

- Sensitivity analysis: Use simulation models to test how the supply chain behaves under different disruption scenarios.

- Resilience governance: Define roles, processes, and KPIs for resilience (e.g., “time to recovery,” “time to impact”) and incorporate them in your business continuity planning.

- Embed Sustainability & ESG

- Sustainable practices: Incorporate ESG (environment, social, governance) into your supply chain resilience strategy — this helps future-proof against regulatory and reputational risks.

- Green logistics: Optimize transport routes to minimize emissions, use eco-friendly packaging, and engage suppliers in sustainability goals.

- Ethical sourcing: Make sure suppliers uphold labor standards, which can reduce risk (e.g., regulatory, supply chain breakdown).

- Invest in People & Culture

- Workforce development: Train your team in resilience practices — risk management, scenario planning, cross-functional coordination.

- Resilience mindset: Encourage a culture of continuous monitoring, learning, and improvement. Not just responding to crises, but being proactive.

- Monitor & Continuously Improve

- Control tower: Use a digital control tower for real-time visibility, central decision-making, and predictive alerts.

- KPIs for resilience: Track resilience-specific metrics like recovery time, service level variability, risk exposure, and flexibility.

- Feedback loops: After every disruption or near-miss, run a “post-mortem” to update plans, refine models, and strengthen weak links.

- Governance & Strategic Alignment

- Executive buy-in: Make sure resilience is part of your company’s strategic priorities, not just a supply chain initiative.

- Cross-functional collaboration: Involve procurement, operations, finance, risk, and sustainability teams in resilience planning.

- Iterative roadmap: Build a multi-year roadmap for resilience investments (technology, capacity, relationships) — adapt it as your business evolves and risks change.