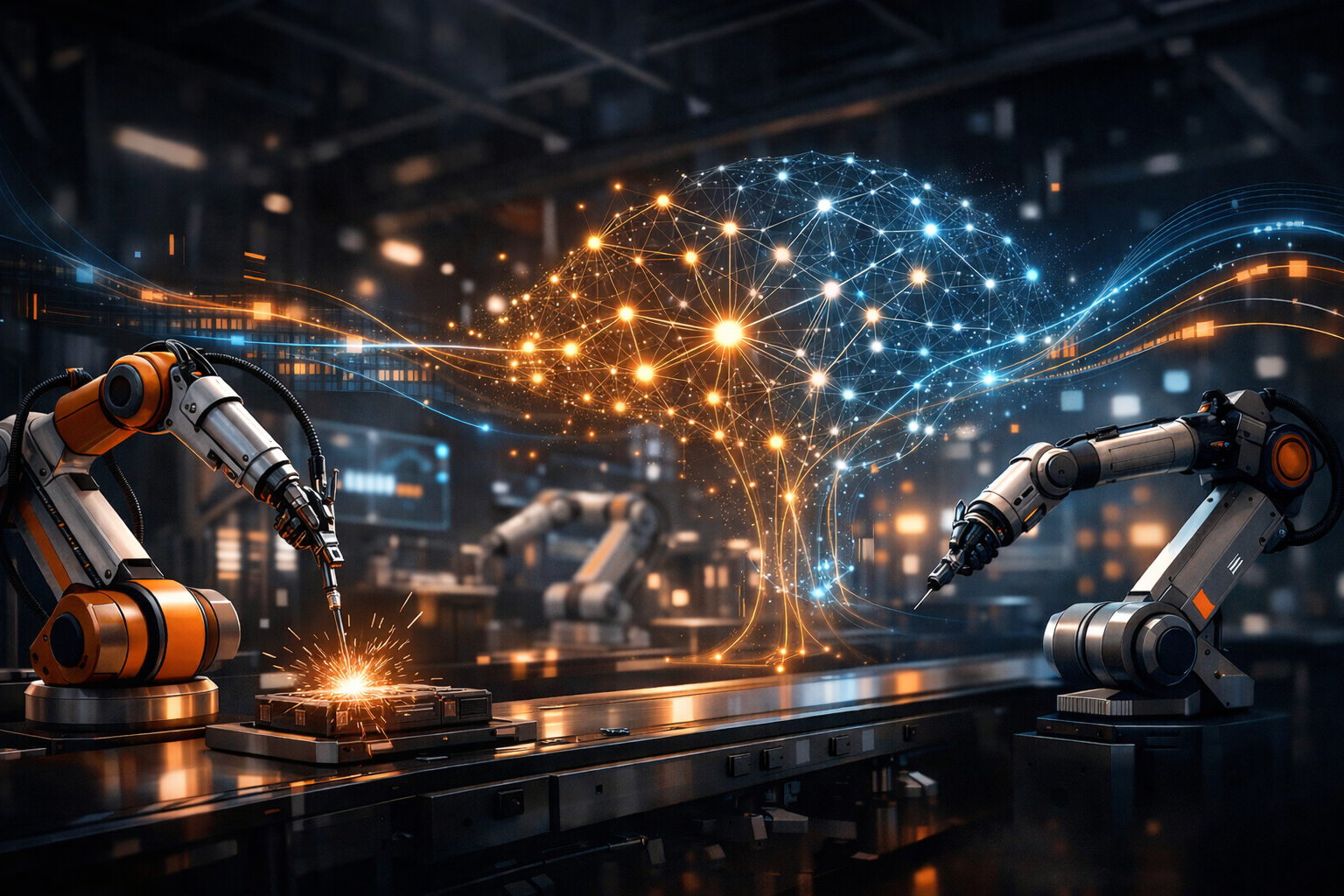

The convergence of artificial intelligence (AI) and manufacturing is no longer a futuristic vision — it’s a present-day imperative. As enterprises vie for greater productivity, efficiency, and competitiveness, AI has emerged as a transformative force. From predictive maintenance to quality inspection and supply-chain optimization, AI is revolutionizing how goods are made. Yet, adoption is not without its challenges. Let’s explore the key barriers and breakthroughs shaping AI’s role in enterprise manufacturing.

Why AI Matters in Manufacturing

AI is rapidly redefining operational excellence. Manufacturers are leveraging machine learning (ML), computer vision, and data analytics to:

- Enhance Quality Control: Detect defects and anomalies with precision using AI-powered computer vision.

- Predict Equipment Failures: Shift from reactive maintenance to predictive maintenance, reducing downtime and maintenance costs.

- Optimize Production Efficiency: Improve throughput and reduce waste through real-time process optimization.

- Streamline Supply Chain: Forecast demand and manage inventory more intelligently.

Despite the clear value proposition, mainstream AI adoption within manufacturing is still uneven.

Top Barriers to AI Adoption

1. Data Complexity and Quality Issues

Data is the backbone of AI. Yet in manufacturing environments, data is often fragmented, siloed, and inconsistent:

- Machines from different vendors generate data in incompatible formats.

- Historical operational data may be incomplete or inaccurate.

- Legacy systems lack the infrastructure for effective data management.

This makes building reliable AI models difficult.

2. Legacy Infrastructure and Integration Challenges

Many manufacturing floors still rely on decades-old equipment and software. Integrating these systems with modern AI platforms often requires:

- Substantial upgrades to OT (Operational Technology)

- Middleware for connectivity

- Skilled professionals to manage integration

These requirements translate to significant upfront investment and complexity.

3. Skilled Workforce Gap

AI demands new skills — from data science to AI engineering and industrial analytics. However:

- Many manufacturers lack enough personnel with expertise in AI.

- Training existing staff is time-consuming and expensive.

- There’s competition for AI talent across industries.

This talent gap remains a critical bottleneck.

4. Cultural Resistance and Change Management

AI adoption isn’t only a technology shift — it’s a cultural transformation:

- Workers may fear job loss due to automation.

- Managers might distrust AI recommendations over human judgement.

- Organizations may lack leadership commitment to embrace AI-driven change.

Without cohesive change management strategies, AI projects often stall.

5. Security and Compliance Concerns

AI systems depend on connected networks and cloud platforms — introducing cybersecurity risks:

- Increased attack surface due to Internet of Things (IoT) connectivity

- Proprietary process data requiring secure handling

- Regulatory compliance with data protection laws

Manufacturers must balance innovation with robust security practices.

Breakthroughs Driving AI Adoption

Despite the barriers, several breakthroughs are fueling rapid AI integration in manufacturing:

1. Edge AI and Real-Time Processing

Edge computing enables AI processing directly on the factory floor — close to machines and sensors:

- Reduces latency

- Improves resilience and uptime

- Minimizes data transfer to central servers

Edge AI is making real-time quality inspection and predictive maintenance feasible.

2. Industrial IoT and Unified Data Platforms

The rise of Industrial Internet of Things (IIoT) devices and data lakes has enabled:

- Seamless data collection from diverse equipment

- Standardized data formats

- Scalable repositories for AI model training

This data democratization is critical for AI success.

3. AutoML and AI Tooling for Non-Experts

Automated Machine Learning (AutoML) platforms are simplifying AI development:

- Reduce dependency on expert data scientists

- Enable engineers to build and deploy models quickly

- Provide automated feature engineering and model selection

These tools democratize AI and accelerate adoption.

4. Digital Twins for Simulation and Optimization

Digital twins — virtual replicas of physical assets — allow manufacturers to:

- Simulate production scenarios

- Predict system behaviors

- Optimize performance before making costly changes

Combining digital twins with AI brings powerful insights into complex systems.

5. Collaborative Robots (Cobots) and Smart Automation

AI-driven robotics and cobots are transforming human-machine interaction:

- Assist workers with tasks requiring precision or strength

- Adapt to changing production environments with learning algorithms

- Improve safety and productivity

Cobots bridge the gap between automation and workforce augmentation.

Read Also: AI in B2B Logistics: Automation, Routing, and Real-Time Decision-Making