As global component supply specialists Artemis Aerospace celebrate 25 years of supporting the aviation industry, we take a look back at how things have changed over the last quarter of a century…

It seems somehow appropriate that the TV series Space:1999 was set in the year Artemis Aerospace was launched by Jim and Deborah Scott. Written in the 70s, its sci-fi setting promoted interest in all things aviation and presented the year 1999 as the epitome of futuristic communication. Looking back now to the first week of trading out of the Scotts’s spare room, complete with that essential business tool, the fax machine, it’s quite a contrast to the high-tech set-up of 2024.

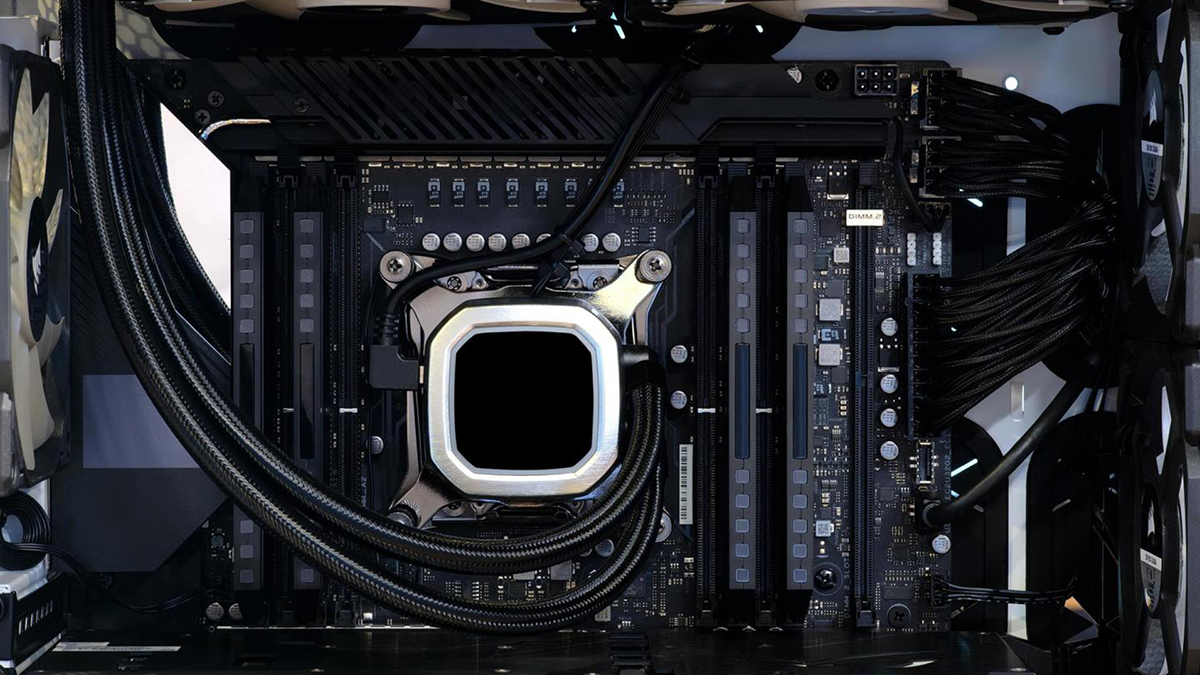

The sophistication of aircraft design and the rate of both technological and commercial advance have accelerated hugely over the last 25 years. Artificial intelligence and machine learning, 3D printing, budget airlines, eVTOL aircraft, the Airbus A380, the Boeing 787 Dreamliner, the replacement of metal structures with composite airframes, ultra long-haul flights, sustainable fuel… the list continues to grow, and as it does, the need for reliable component supply to avoid AOG situations becomes more pressing.

The growth of the worldwide aircraft aftermarket parts sector is estimated to reach USD$47.33 billion by 2028. However, there are considerable challenges for the industry in an era of worldwide political instability post-pandemic. There are significant supply chain issues, due to a scarcity of both labour and raw materials to produce the parts. After the pandemic, demand rocketed, and manufacturers were unable to keep up with it. In addition, some companies folded during the pandemic, and shipping delays due to rerouting are still causing problems. There is not only a global shortage of airline pilots, but also of qualified aviation engineers and experienced technical personnel.

Twenty-five years ago, the newly launched Artemis Aerospace faced similar conundrums, although with a different political background. Vital parts were often out of stock or awaiting production, and there was none of the instant communication which today’s business relies on. Success in the industry was based on the ability to trade astutely and keep ahead of the game, with customer service a much lower priority. The idea behind Artemis, however, was to become known as a facilitator, not just a trader.

“Service and commitment were the only things we could offer at the outset, and we have really tried to maintain the level of both,” Jim says. “We feel we’re only as good as the last time we had a successful outcome for a customer, and this industry throws up all kinds of issues daily. Communication is key, keeping in touch constantly, growing trust and becoming part of a customer’s team so we work in partnership rather than just being a supplier. At the centre of everything we do is an aircraft component, but managing the issues, and the logistics involved in its supply, is crucial.”

The Scotts were determined from the outset to bring terrier-like determination to the hunt for elusive aircraft parts, and this policy of leaving no stone unturned soon began to pay dividends.

As Deborah says, “Once customers realised that we wouldn’t go to sleep at night until the part they needed was delivered, they started coming back to us.”

It’s a permanent battle for airlines to balance component requirements and the need for expensively managed and resourced storage areas. It’s not possible to store every possible part of an aircraft, but inevitably the one needed immediately will be one which isn’t in stock. Other issues can cause headaches – aircraft which may previously have been retired earlier are kept in service for longer, and therefore the components they may have supplied don’t come onto the market. Parts are also essential to keep flight training simulators in use to ensure pilots and cabin crew can complete initial and recurrent training.